By AutoIndústria |Translated by Jorge Meditsch

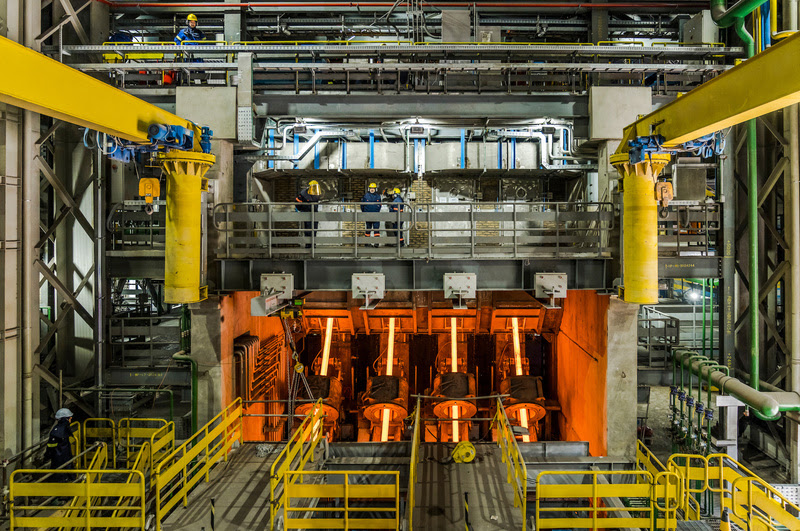

Gerdau announced the beginning of operation of the new bars and billets continuous casting at its plant in Pindamonhangaba, SP, a more automatized process with better performance that provides higher-quality products.

“The unity’s technological update, which demanded a R$ 700million investment, is aligned to the perspective of expansion of electric and hybrid vehicles matrix in Brazil and the current automotive industry’s demand for lighter automobiles”, says the company’s note.

The new equipment installed in the plant will provide gains on three fronts: safety, because it is more automatized and modern; quality, producing “clean steel”, which gives the products more resistance and endurance; and competitiveness because it reduces costs and increases operational productivity.

“We have invested in our special steel plants to increase productivity and meet our customers’ needs and growing demand. The new casting at the Pindamonhangabaplant is aligned to the 4.0 industry and will increase our operations’ quality and competitiveness in this segment”, informed Rubens Pereira, Aços Especiais Gerdau’s vice-president in Brazil.

According to the executive, the plan to modernize operations up to 2025, which still depends on approval by the board of management, “strengthens the company’s optimistic vision of the Brazilian automotive sector, which shall recover its production level recovered in the mid and long-term”.

The investments under study will include, besides Pindamonhangaba, the units in Mogi das Cruzes, SP, and Charqueadas, RS. Gustavo Werneck, Gerdau’s CEO, emphasizes the profound cultural and digital transformation the company went through over the last years, “which made it even more focused on people, more digital, innovative, diverse and inclusive”.

The investment in Pindamonhangaba is part of a R$ 1 billion plan announced last year, which also involves the reactivation of the steel mill at the plant in Mogi das Cruzes, generating 150 new direct jobs. The plant has been hibernating since March 2019 and is now operating with an early capacity of 180 thousand tons of steel, which is laminated in Pindamonhangaba.

At the Charqueadas plant was installed a new steel bars annealing and spheroidizing furnace providing more quality and productivity to the productive process, competitiveness gains and new personal safety concepts.

Photograph: Gerdau