By Redação AutoIndústria| 8/30/23 | Translated by Jorge Meditsch

Producing battery systems in its plant in Piracicaba, SP, since February, BorgWarner has ambitious growth plans in the area and is currently searching for new suppliers to expand product localization.

“We have plenty of space for future expansion, which enables us to respond to new demands by manufacturers faster”, said Marcelo Rezende, BorgWarner’s battery systems general director in Brazil.

According to the executive, the aim is to multiply the Piracicaba plant revenue by 20 in five years, quadruple the number of employees, and assemble the complete system in the country, including the battery.

Occupying a 33 thousand square-meter area, with 10 thousand square meters of built area and 2.3 thousand square meters of plant area, the Brazilian plant is one of the four owned by the group worldwide – the others are in the United States and Germany.

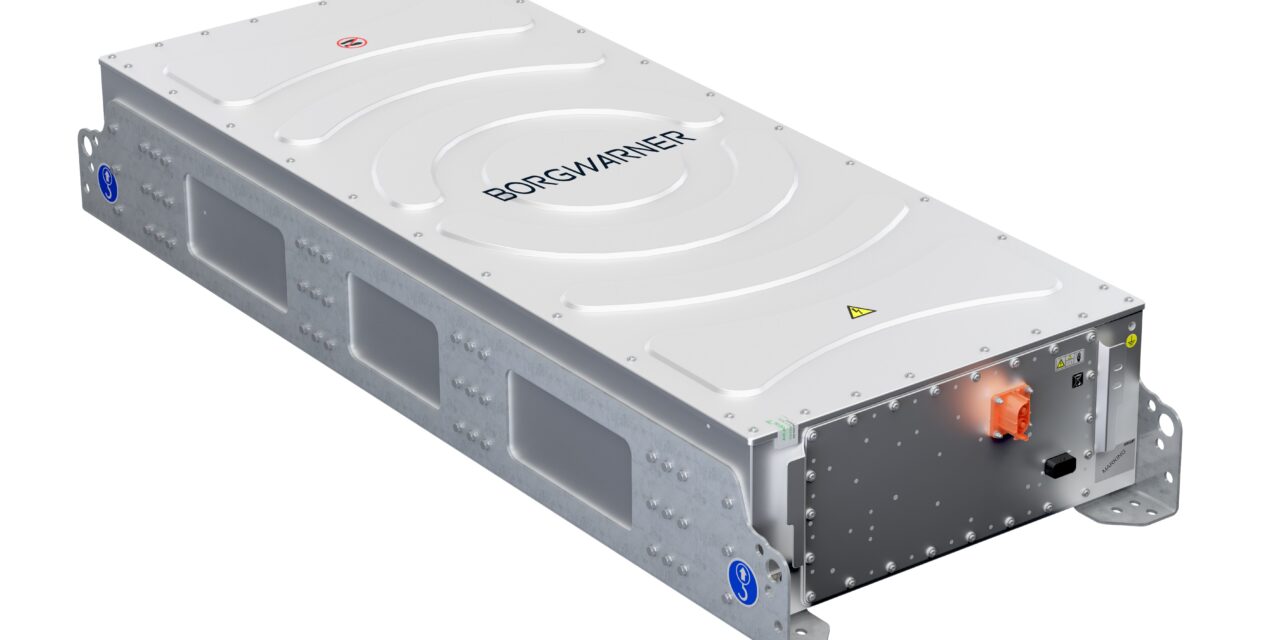

In Piracicaba are currently assembled the Battery Management System (BMS), Junction boxes, the Direct Current Charging Unit (DCCU) and the Electric Drive Control Unit (EDCU). At the end of the process, the components undergo a series of performance and safety tests by last-generation equipment.

BorgWarner’s first customer in Brazil was Mercedes-Benz, which equips its electric buses with its batteries. Volvo is also negotiating to become a local customer.

“Battery systems made in Piracicaba have a high energy density, providing more vehicle autonomy, ” explains Rezende. “The battery we assemble the systems for was developed for intensive energy use applications, operating at up to 665 Volts and storing 98 kWh.

BorgWarner explains that a battery systems plant capacity is measured by the energy storage capacity of the products it makes.

The current capacity of the plant in Brazil is 500 MWh. The factory’s battery systems production can store enough energy to supply 250 homes for one year or a bus to ride non-stop 300 thousand kilometers in the city traffic.

According to the company, local battery production for electric vehicles can contribute directly to electric mobility expansion in Brazil.

“As they are a strategic component for these vehicles, the localization makes the process more viable, safe, productive and sustainable. Besides that, developing the battery in Brazil sharing technology and technical know-how with Brazilian professionals foments the local industry and qualifies the national workforce”, highlights the manufacturer’s note released this week.

For Rezende, it is extremely relevant for Brazil to have a clean energy matrix “that can be potentialized through modern manufacture processes created to be sustainable all over the production chain”. He also remembered that BorgWarner provides all technical assistance services for the batteries it produces locally.